Egeflex 2 CO

100

Synthetic oil resistant rubber

Abrasion, weather and heat resistant synthetic rubber

-40

+100

Oil

Two braids of steel wire

1:4

A hose for applications with medium to high pressures and a lot of external abrasion. Equivalent to EN 853 2SN. Approved by MSHA (flame resistant). The certificates refer to dimensions 3/16" – 1".

Part numbers ending in -30 are supplied on a reel. Joints can occur, maximum 4 lengths/bobbin and a minimum length of 5 meters per length.

4200-12-xx, 4200-22-xx, 4200-23-xx, 4200-32-xx

Other

Material Codes

| Part no. | ID mm | ID inch | OD mm | Bend rad mm | Max length | WP MPa | Length min. | Weight kg/m |

|---|---|---|---|---|---|---|---|---|

| 11021404 | 6,50 | 1/4" | 14.4 | 100 | - | 40 | - | 0.31 |

| 11021405 | 8 | 5/16" | 16.0 | 115 | - | 35 | - | 0.37 |

| 11021406 | 10 | 3/8" | 18.4 | 130 | - | 33 | - | 0.44 |

| 11021408 | 13 | 1/2" | 21.4 | 180 | - | 27,50 | - | 0.53 |

| 11021410 | 16 | 5/8" | 24.6 | 200 | - | 25 | - | 0.66 |

| 11021412 | 19 | 3/4" | 28.6 | 240 | - | 21,50 | - | 0.84 |

| 11021416 | 25 | 1" | 37.1 | 300 | - | 16,50 | - | 1.23 |

| 11021420 | 32 | 1 1/4" | 46.7 | 420 | - | 12,50 | - | 1,77 |

| 11021424 | 38 | 1 1/2" | 54.5 | 500 | - | 9 | - | 2.17 |

| 11021432 | 51 | 2" | 66.07 | 630 | - | 8 | - | 2.79 |

| 1102140430 | 6,50 | 1/4" | 15,0 | 100 | 210 | 40 | 150 | 0,33 |

| 1102140530 | 8 | 5/16" | 16,6 | 115 | 175 | 35 | 105 | 0,39 |

| 1102140630 | 10 | 3/8" | 19.0 | 130 | 135 | 33 | 95 | 0,50 |

| 1102140830 | 13 | 1/2" | 22,2 | 180 | 95 | 27,50 | 65 | 0,59 |

ASSEMBLY INSTRUCTIONS FOR REUSABLE FITTINGS WITH NON-SKIVE FERRULES ON HIGH PRESSURE HOSES EN 853 1SN AND EN 853 2SN

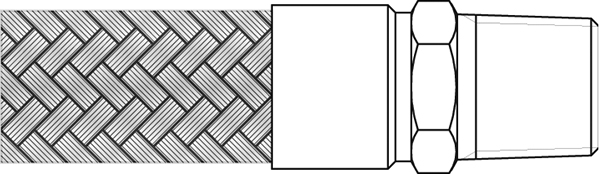

1. Cut the hose transversely. Secure the fitting ferrule in a vice. Make sure you are using the right ferrule, with one or two rings around the neck. One ring for 1SN-hoses and two rings for 2SN-hoses.

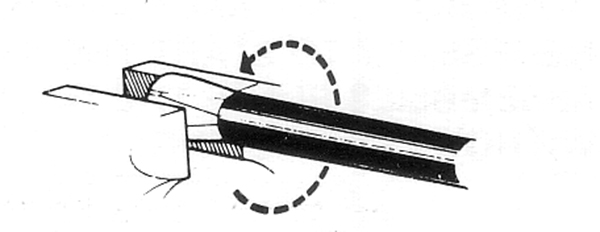

2. Screw the hose on the ferrule until it stops. The fitting ferrule has left-handed threads.

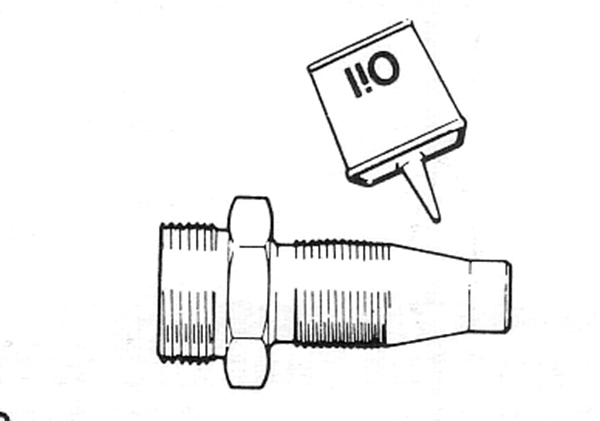

3. Lubricate the hose and the insert. Place the ferrule in the vice. Insert the nipple so far that the hexagonal meets the ferrule.

|

|