EGEFLEX 2 HT

100

Synthetic oil resistant rubber

Weather- and oil resistant rubber

-40

+150

Oil

Two braids of steel wire

1:4

The hose is suitable for high pressure lines for oil, fuel or lubrication systems with exta high temperature. Equivalent to EN 853 2SN.

Blue, wrapped

4200-22-xx, 4200-23-xx, 4200-32-xx

| Part no. | ID mm | ID inch | OD mm | Bend rad mm | WP MPa | Weight kg/m |

|---|---|---|---|---|---|---|

| 11025004 | 6,50 | 1/4" | 15,2 | 100 | 40 | 0,40 |

| 11025006 | 10 | 3/8" | 19,1 | 130 | 35 | 0,60 |

| 11025008 | 13 | 1/2" | 22,1 | 180 | 29,70 | 0,68 |

| 11025010 | 16 | 5/8" | 25,2 | 200 | 22,70 | 0,80 |

| 11025012 | 19 | 3/4" | 29,5 | 240 | 21 | 1,00 |

| 11025016 | 25 | 1" | 37,9 | 300 | 17,50 | 1,44 |

| 11025020 | 32 | 1 1/4" | 48,8 | 420 | 15,70 | 2,39 |

| 11025024 | 38 | 1 1/2" | 54,6 | 500 | 12,20 | 2,60 |

| 11025032 | 51 | 2" | 67,8 | 630 | 10,50 | 3,38 |

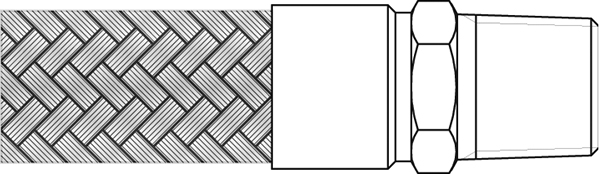

ASSEMBLY INSTRUCTIONS FOR REUSABLE FITTINGS WITH NON-SKIVE FERRULES ON HIGH PRESSURE HOSES EN 853 1SN AND EN 853 2SN

1. Cut the hose transversely. Secure the fitting ferrule in a vice. Make sure you are using the right ferrule, with one or two rings around the neck. One ring for 1SN-hoses and two rings for 2SN-hoses.

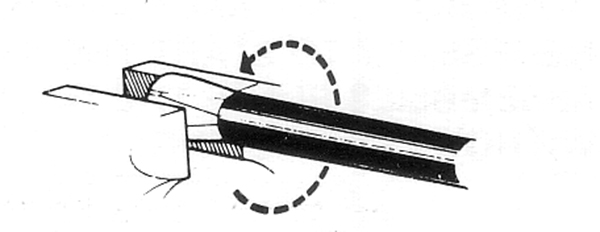

2. Screw the hose on the ferrule until it stops. The fitting ferrule has left-handed threads.

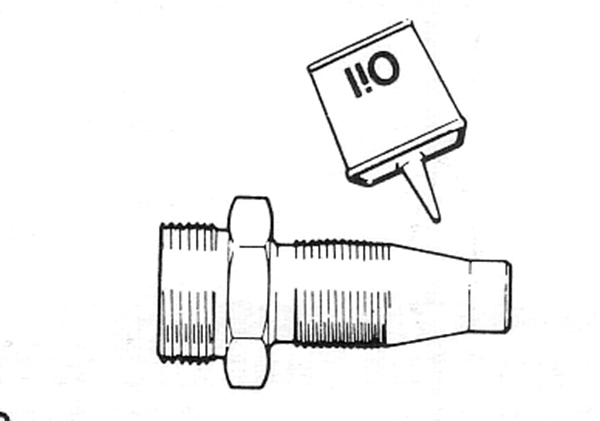

3. Lubricate the hose and the insert. Place the ferrule in the vice. Insert the nipple so far that the hexagonal meets the ferrule.

|

|